HYDRONIC HEATING

Hydronics is the use of water as a heat transfer medium in heating and also cooling. Historically systems were high temperature baseboard systems. But with plastic tubing being developed that can withstand higher temperatures, hydronics has evolved into in-floor systems in which the floor can become the heat emitter for a truly low temperature system for higher boiler or heat pump efficiencies. Even solar collectors can have a place in a low temperature system design.

|

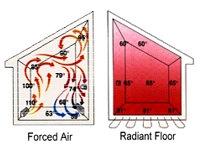

Comfort and convenience are important advantages to hydronic heat. Heat is evenly radiated throughout the room to maintain comfort without cold spots. The system is completely quiet as pumps and boiler are located in the Mechanical Room away from the living areas. No room noise from air flow through the heat registers as in a forced air system. In fact floor space is completely uncluttered. No worry about placement of furniture to accommodate the heating system. Finally the circulation of dust and other airborne particles is eliminated. As is the yearly cleaning of the air ducts.

The radiant nature of hydronic heat means that objects are heated not the air, so very little temperature stratification. And, as such, lends itself well to open cathedral ceilings. And since “we” are one of the objects being heated, most often the thermostat can be lowered for energy savings.

|

ENERGY eFFICIENCY

Energy efficiency is one of the many advantages hydronic heat offers over the typical forced air systems or even the baseboard water systems. Low water temperatures are the norm for an in-floor system as the entire floor is emitting heat. This pushes today’s condensing boilers to their maximum efficiencies in excess of 95% efficient. Heat pumps also gain efficiencies with the lower load water temperatures. Solar collectors can even play a role in space heating. Low temperatures pushes solar collectors to high efficiency.

Other efficiencies to be noted is the heat delivery system. Water is moved by fractional hp pumps. Maybe 3 or 4 pumps in a well designed system of 1/25hp each vs. a 1/2hp blower for a forced air system. (Today’s pumps are variable speed for better efficiency and increased life.) Air ducts and ensuing air leaks are eliminated. Further efficiencies are realized in zoning of heated areas and areas, such as the spare bedroom, which do not require heat on a regular basis. While zoning is possible with a forced air system, it is not convenient or exact. The hydronic system just requires a shutoff valve and a thermostat. Finally is the ease of routing the delivery system. A ¾ inch hydronic header can deliver as much heat as an 8x14 inch air duct. Nice in limited areas such as crawl spaces. And insulation of the ¾” line is far easier and more effective than insulating the air duct if ran in a non-heated area. |

Bottom Line: A well designed hydronic heating system is a high value addition to your project. Generally the initial cost will be more than a forced air system but can pay for itself in energy savings, with comfort as an added bonus. Given the longer service life, a hydronic system could actually be the less expensive system when considering Life-Cycle cost.

Visit the More...Other Resources tab for more information on Hydronic Heating.